Canopy | Canopy Gull Wing Door | Completed Gull Wing Door | Canopy Door Support | Flight Controls | Elevator Trim Tab

Corvair Engine (page 1) | Corvair Engine (page 2) | Dual Facet Fuel Pumps | Oil Cooler & Filter | Oil Cooling System

Engine Baffles | Intake & Exhaust | Corvair Engine Starter Mount | Dual Ignition | Corvair Engine Mount | LED Rudder Nav Light

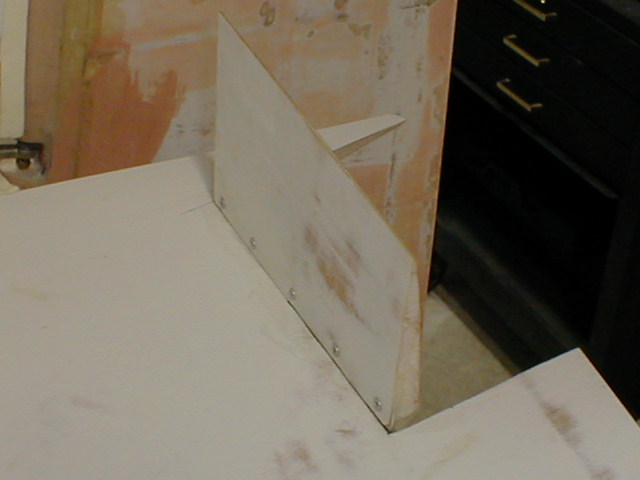

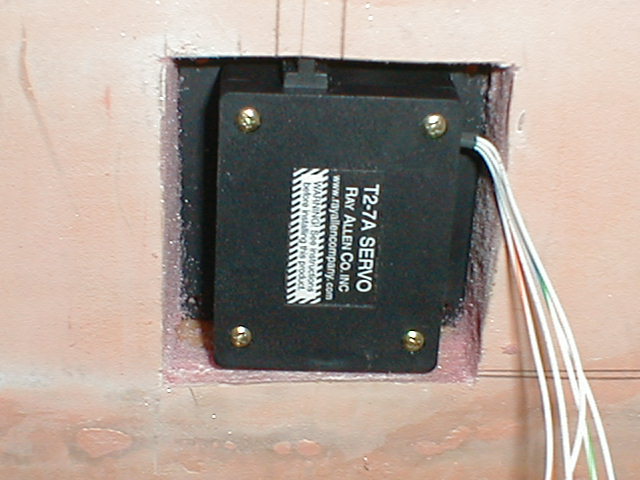

Matco Brakes & Diehl Gear | Secure Distributor & MSD Wires | Belly Board Speed Brake | Spars & Stub Wing (page 1)

Stub Wing (page 2) | Wing, Landing Light, Wing Tip | N886MJ Goes To The Airport | Lost My Spinner | My Car Tags

Sensenich Propeller | CorvAIRCRAFT Engine | Body Work & Paint

A TRIBUTE TO KEN RAND