|

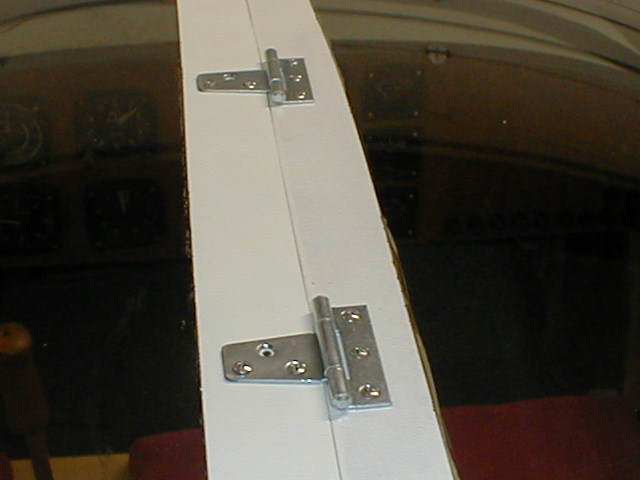

The following photos are of my canopy and gull wing door set

up. The frame as you can see, only encompasses the door and does not extend across the canopy.

Increased visibility was the purpose for doing this. Draw back is the frame is not a built in roll bar. The

canopy was positioned on the forward deck and turtle deck and glassed in place using carbon fiber.

Once the canopy frame was finished, I proceeded to cut the

section of canopy out which would become the

door. I masked the door frame area and drew my lines. With

a Dremel Tool and a cut off wheel, I ever

so carefully cut the canopy door out. To make up a door frame, I

used 1/8" x 3" Oak strips. First, I laminated the first strip to

the fixed canopy where the door was cut out using T-88 epoxy and clamping and allowing each layer to

cure before applying the next Oak strip. This process took

five days since I laminated five layers of oak

to make the frame. The corner of the door frame was interlapped

creating a very strong joint. Only 1 1/2" of

the 3" width of the strip was laminated to the canopy. After all

laminating was finished and cured, I very

carefully, using a jig saw, cut out the half of the frame work which

was not laminated to the fixed canopy. This

resulted in a perfect match for that portion of the door frame. The

rear door frame, which mates to the turtle

deck, was done in a similar fashion except I laminated three layers

of fiberglass and 1/4" lastofoam, kind of

making a triple decker sandwich in which to cut the rear frame from.

This was then laminated to the door glass with

T-88 epoxy. The hinges are very simple. They are slightly

modified "barn door" hinges purchased at the

local hardware store. There will be locking pins installed in all

four corners of the door for that positive

closure and locking security. |

|